| Grade | Ni | Cr | Fe | Mn | C | Cu | Si | S | Al | Ti | Mo |

| Alloy 825 | 38.00-46.00 | 19.50-23.50 | ≥22.00 | ≤1.00 | ≤0.05 | 1.50-3.00 | ≤0.50 | ≤0.03 | ≤0.20 | 0.06 -1.20 | 2.50-3.50 |

Incoloy 825 Pipe

Products Description

Incoloy 825 pipe is a high-performance nickel-iron-chromium alloy pipe. With its excellent corrosion resistance and comprehensive mechanical properties, it plays an important role in many industrial fields.

Incoloy 825 pipe has excellent resistance to a variety of corrosive media such as sulfuric acid, phosphoric acid, and organic acids. It shows good stability in both reducing and oxidizing environments, and can effectively prevent problems such as pitting, crevice corrosion, and stress corrosion cracking. It has high strength and hardness, as well as good ductility and toughness. It can maintain stable mechanical properties in both high and low temperature environments, making it adaptable to various complex working conditions. It has a wide long-term operating temperature range and can operate stably in the temperature range of -200℃ to 500℃. The short-term operating temperature can even reach 800℃, which is suitable for applications in high temperature environments.

Incoloy 825 Equivalent Materials

| INCOLOY 825 | UNS | W.Nr. | DIN |

| N 08825 | 2.4858 | NiCr 21 Mo |

Chemical Composition:

Incoloy 825 Pipe Physical Properties:

| Grade | Density | Melting Point |

| Incoloy 825 | 8.83 g/cm3 | 1300°C-1390°C |

Product Photos

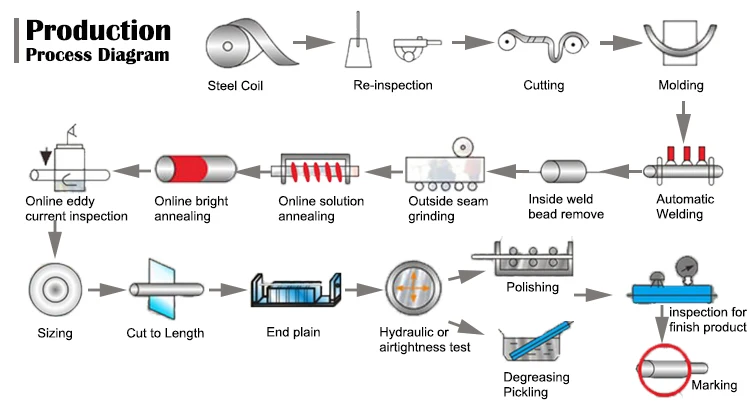

The manufacturing process of Incoloy 825 tube:

1. Raw material preparation: Select standard Incoloy 825 alloy materials, including raw materials of major elements such as nickel, chromium, iron, molybdenum, and copper.

2. Melting: The raw materials are melted by vacuum induction melting (VIM), electroslag remelting (ESR) or vacuum arc remelting (VAR) to obtain alloy ingots with uniform composition and high purity.

3. Hot working: The ingot is heated to an appropriate temperature for hot extrusion or hot rolling to form a tube blank. This process helps to improve the microstructure and properties of the alloy and initially form the shape of the tube.

4. Perforation: The tube blank is processed into a hollow rough tube using a perforation process. Common perforation methods include pressure perforation, push perforation, etc.

5. Cold working: The rough tube is cold drawn or cold rolled to further accurately control the size of the tube and improve the surface quality, reduce the wall thickness and outer diameter, and achieve the required specifications.

6. Heat treatment: According to the requirements of the product, appropriate heat treatment is carried out, such as solution treatment, annealing, etc. Solution treatment usually involves heating the pipe to a certain temperature and keeping it warm for a period of time before rapid cooling to improve the structure of the alloy and improve its performance and corrosion resistance.

7. Surface treatment: The pipe is pickled, polished and other surface treatments are performed to remove the oxide scale and impurities on the surface and improve the surface finish.

8. Nondestructive testing: Nondestructive testing methods such as ultrasonic testing (UT), eddy current testing (ET), and radiographic testing (RT) are used to check whether there are defects inside and on the surface of the pipe, such as cracks, pores, inclusions, etc.

9. Cutting and packaging: The pipe is cut according to the length required by the customer and properly packaged to prevent damage and corrosion during transportation and storage.

Our factory

Steel Making

Ingot Production

Forged Bars

Machinary

Applications

Due to its excellent performance, Incoloy 825 pipe is widely used in the following fields:

1. Chemical industry: used for transmission pipelines of various corrosive media in chemical production, such as strong acid, strong alkali, organic solution, etc.; heat exchange tubes of chemical reaction vessels; pipeline systems in fertilizer production, pesticide manufacturing, chemical fiber production, etc.

2. Oil and gas industry: plays an important role in the exploitation, processing and transportation of oil and gas fields. It can be used for the exploitation pipelines of sulfur-containing oil and gas fields; seawater pipeline systems of offshore oil platforms; parts of oil and gas pipelines that deal with corrosive media; heat exchanger tubes and pipelines in the process of petroleum refining, etc.

3. Environmental protection engineering: used for corrosive wastewater pipelines in wastewater treatment plants; transmission pipelines for corrosive gases in waste gas treatment systems; pipelines for high temperature and corrosive media in waste incineration plants, etc.

4. Marine engineering: in marine environments, such as pipelines of seawater desalination devices; firefighting pipelines and seawater cooling pipelines on offshore platforms; submarine pipelines, etc., can effectively resist seawater corrosion and erosion of the marine environment.

5. Pharmaceutical industry: Pipes used to transport various corrosive liquid medicines, solvents and other media during the drug production process.

6. Food industry: Pipes used to process and transport food raw materials or additives with certain corrosiveness, such as acidic foods, food processing solutions containing chloride ions, etc.

Energy industry: Pipes and heat exchanger tubes used to process and transport corrosive media in related systems such as nuclear power generation and thermal power generation.

Quality test Equipments

Packing & Delivery

Packing & Delivery

-

The inner size of container is below:

-- 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high)

-- 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high)

-- 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high)

We always adhere to a strict quality management system, and carry out strict quality control in every link from raw material procurement to production and processing, finished product inspection, etc. Each Incoloy 825 pipe undergoes multiple inspections such as chemical composition analysis, mechanical properties testing, non-destructive testing, and dimensional testing to ensure that the product quality meets international standards and customer requirements.

Choose our Incoloy 825 pipe to provide you with reliable, efficient, and corrosion-resistant piping solutions for your industrial system, helping your project succeed.

Hot Tags: incoloy 825 pipe, China incoloy 825 pipe manufacturers, suppliers, factory, stainless mechanical tubing, 4140 Alloy Steel Plate, 45NiCrMoV16 6 Alloy Steel Bar, stainless steel flat metal, 9mm stainless steel rod, 3 stainless steel exhaust pipe

Previous

Alloy 825 TubingYou Might Also Like

Send Inquiry